Contents:

- Dating an A24 by sail number.

- Sail number register.

- Introduction.

- History (by Butler Mouldings).

- Principle Dimensions.

- Rig and Sail Dimensions.

- Standard Specification.

- Standing Rigging.

- Running Rigging.

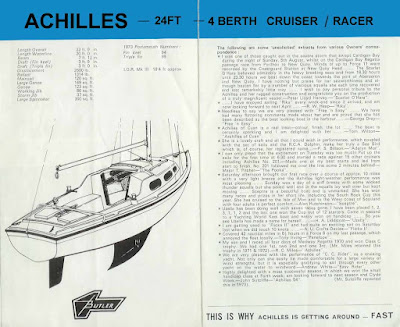

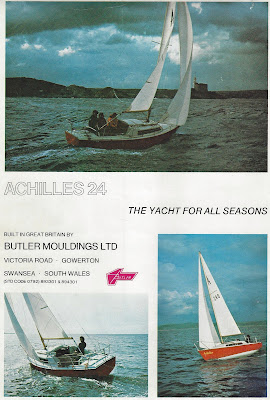

- Brochures.

- Deck Hardware.

A24 Sail Numbers by date.

|

| Estimated year of production derived from year boats were displayed at shows. |

Sail number register.

Notes on the sail number register:

- Where the sail number is not known then the boat is listed randomly at the end.

- Boat names in brackets are previous names.

- Keel & Rig - If there is no note then it is assumed to be fin keel and masthead rig.

- Location: If from Butler’s list then location is location of owner or first owner if more than one. The full addresses are not listed for privacy reasons.

- Underlined links are to the an owners page in the Flickr Achilles Group, email or web site / blog, this may not be the current owner. Those from the old site found to be invalid are omitted.

Introduction.

|

| An Ajax 23 racing off St Mawes. Picture: John Lashbrook. |

Around 600 were built from 1968 until production finished in 1985 with some completed from kits by their owners. With her moderate beam and fine lines the Achilles 24 has an easily driven well balanced hull.

In an April 2006 review of the best second-hand yachts between 22 and 24 feet, Practical Boat Owner magazine noted of the Achilles 24 that 'If looking for performance you won't do much better than this slippery little number from the board of Oliver Lee'.

Sailing Today magazine published a comprehensive and well illustrated review of sail number 463 in their September 1999 issue, and much earlier in April 1971 Yachts and Yachting magazine reviewed sail number 50 which was the Achilles 24 demonstrator boat at that time. The reviews said things like 'This is a boat from which I could get lots of enjoyment', and 'The Achilles is a joy to sail'.

History (by Butler Mouldings).

In 1967 Oliver Lee produced a design for a 19ft open keelboat. A wooden hull was built and sailed and on being found to be a excellent boat she was used as a plug for a G.R.P. mould, and so started production of the Squib. The Squib is still in production today with over 800 having been built, surely testement to any designer and design. The Squib was first built by the Essex Boat Company, and a request was made that Oliver Lee should design a full deck with coachroof for her. This he did and the version was called the Hunter 19 with the Essex Boat Company becoming the now well known Hunter Boats. The Squib had been derived from a larger design by Oliver Lee from 1966, a 7/8ths rig 23 ft keelboat called the Ajax. Some 60 Ajax's were built by around 1968 and she proved a successful boat, her sailing qualities such that she was put forward as a contender for selection as a class for the 1972(?) Olympics, losing out to the Soling. However the Ajax was also an open boat and it was considered that she would have more appeal as a cruiser/racer and a deck moulding was designed and produced as for the Squib. The decked version of the Ajax was called the Achilles.

|

| A Family affair, Father and son in Goskar and Chilli Pepper respectively. St Mawes in the background. |

The first Achilles design was improved by Chris Butler of Butler Mouldings. He added four inches to her freeboard which increased the headroom below and gave the Achilles the distinctive knuckle below her sheer line. This also increased her overall length and she became known as the Achilles 24. The rig was changed from 7/8ths to masthead and the draught slightly increased with the shape of the ballast keel altered to lower the centre of gravity and give the keel a very efficient bulb shape.

|

| A24 "Hotfoot" sailing by A9m "Sancerre", St Mawes, 2020, before coming alongside. Picture: John Lashbrook, Video below by Ron Dustow. |

Butler Mouldings began to build the Achilles 24 and sail number 17 was exhibited at the 1970 London Boat Show. The class soon gained a good reputation reaching sail number 350 after only four years with the class being exhibited and sold all over Europe. The Achilles 24 was also available as a kit for completion by the owner. An early review concluded that for a small yacht the Achilles was 'hard to fault' and 'exciting to sail'.

|

| A24 "Mischief" just arrived in Baltimore harbour at the end of the 2019 Jester Baltimore, "Bernie" is a big lad and makes the boat look even smaller! Photo: John Lashbrook. |

Two keel options were available, a single fin or a slightly shallower draft triple fin that allowed the boat to take the ground safely without any other support. The triple keel version retained a 7/8ths rig until about sail number 170 after which a masthead rig was used.

|

| One of the Triple keel A24's, pic by Jason McIntyre. |

The deck moulding was also redesigned during the Achilles 24 production. The earlier boats had a chain locker but no anchor locker so that the anchor had to be stowed on the foredeck or elsewhere below. This was changed at around sail number 250 when an anchor locker was added. Sometime later, possibly sail number 350 onwards, the cockpit coaming at the main hatch was raised from its original height of two inches and a bridge deck was made across the companionway at the height of the cockpit seats. For the record my boat, sail number 302, has the anchor locker but retains the low coaming in the cockpit.

There were also detail changes to the design. The cabin widows in the earlier boats were rubber mounted perspex with three separate windows on each side. This was later changed to a single tinted sheet of perspex on each side. At the same time the shroud chain plates were moved inboard to the coach roof from just inside the toe rail, allowing a tighter sheeting angle with the headsails. On the foredeck the single cleat was discontinued and twin cleats used, and in the cockpit the locker hinge scuppers were redesigned. There were also changes to the galley during the boats production. By the time production ended some 600 Achilles 24's had been built.

|

Principal Dimensions.

Waterline length 19 ft 6 ins (5.94m)

Beam 7 ft 1 ins (2.14m)

Draught fin keel 3 ft 9 ins (1.14m)

Draught triple keel 3 ft 3 ins (1 m)

Hull GRP

Deck GRP balsawood sandwich

Displacement 2600lbs (1180kg)

Ballast 1314lbs (596kg) iron bulb

Sail area 206 sq ft (19.15 sq m)

Accommodation 4 berths

Headroom 4 ft 6 ins (1.37m)

Sail Plan Dimensions.

|

Luff |

Leech |

Foot |

Area |

|

|

Mainsail |

22' 3" |

24' |

10' |

111 |

|

Max IOR Genoa |

25' 9" |

25' 7" |

11' 11" |

154 |

|

No2 Genoa |

24' |

23' 3" |

11' 3" |

129 |

|

Long Luff Jib |

24' |

23' 3" |

9' |

101 |

|

Working Jib |

21' 3" |

18' 6" |

9' 4" |

87 |

|

Storm Jib |

17' |

13' 6" |

6' 9" |

42 Max |

|

Spinnaker |

25' 6 |

25' 6" |

Max Width

- 13' 91/2" |

350 |

Achilles 24 Standard Specification - 1 Sept 1979

Hull/Deck Unit.

Ballast Keel (Single Fin).

Ballast Keel (Triple Fin).

Rudder, Skeg and Tiller.

Accommodation.

Spars and Rigging.

Spinnaker Equipment.

Ground tackle.

Engine.

Standard Safety Equipment.

Standard Deck Fittings.

Standing Rigging (1977).

|

Cap Shrouds (2 of) |

5mm 1 x 19 S/S complete with Hasselfors |

25' 10" |

|

swaged end bottle screws. |

||

|

Forestay |

5mm 1 x 19 S/S complete with Hasselfors |

26' 8" |

|

swaged end bottle screws. |

||

|

Backstay |

5mm 1 x 19 S/S complete with Hasselfors |

24' 8" |

|

swaged end bottle screws. |

||

|

Fwd Lower Shrouds |

5mm 1 x 19 S/S complete with Hasselfors |

13' 8" |

|

(2 of) |

swaged end bottle screws. |

|

|

Aft Lower Shrouds |

5mm 1 x 19 S/S complete with Hasselfors |

13' 9" |

|

(2 of) |

swaged end bottle screws. |

|

|

Divided Lower Backstay |

5mm 1 x 19 S/S complete with Hasselfors |

11' 0 |

|

swaged end bottle screws. |

- Do not use these dimensions to order new rigging – CHECK on your own boat.

- The dimensions for the backstay and divided lower backstay do not add up?

Running Rigging (1977).

|

Mainsail Halyard |

8mm Prestretched 3 Strand Terylene |

62ft (19 Meters) |

|

Foresail Halyard |

8mm Prestretched 3 Strand Terylene |

62ft (19 Meters) |

|

Main Sheet |

10mm 8 Plait White Matt Terylene |

45ft (14 Meters) |

|

Foresail Sheet |

10mm 16 Plait Gold Terylene |

50ft (15 Meters) |

|

Reaching Sheet |

10mm 8 Plait White Terylene |

23ft (7 Meters) |

|

Topping Lift |

6mm 8 Plait Prestretched Terylene |

50ft (15 Meters) |

|

Mainsail Clew Outhaul |

6mm 8 Plait Prestretched Terylene |

8ft (2.5 Meters) |

|

Kicking Strap |

8mm 8 Plait Prestretched Terylene |

10ft (3 Meters) |

|

Cunningham Eye |

6mm 8 Plait Prestretched Terylene |

8ft (2.5 Meters) |

|

Backstay Tensioner |

6mm 8 Plait Prestretched Terylene |

12ft (4 Meters) |

|

Foreguy |

6mm 8 Plait Prestretched Terylene |

15ft (4.5 Meters) |

|

Burgee Halyard |

2mm Plaited Terylene |

45ft (14 Meters) |

|

Spinnaker Halyard |

8mm Prestretched 3 Strand Terylene |

62ft (19 Meters) |

|

Spinnaker Sheet Port |

10mm 8 Plait Red Matt Terylene |

35ft (10.5 Meters) |

|

Spinnaker Sheet St'bd |

10mm 8 Plait Blue/Green Matt Terylene |

35ft (10.5 Meters) |

|

Spinnaker Uphaul |

6mm 8 Plait Gold Terylene |

30ft (9 Meters) |

|

Spinnaker Downhau |

10mm 8 Plait White Terylene |

27ft (8 Meters) |

1 off Stemhead roller (Yacht Services 7134).

6 off 1/4" UNC c/sk screws,

1 1/4" to 2", c.w. nuts & washers.

1 off UB7 "U" bolt for forestay (Main Marine).

c.w. 1 off forestay tack snap shackle MD.126 (Brookes & Adams).

2 pairs handed fairleads (Yacht Services 4" No.7120).

8 off 5mm x 1" c/sk screws, c.w. nuts & washers.

1 off water filler cap (SL.1786-1) & label (SL.1787).

March 1978 added key (SL.1788).

4 off 5mm x 1" screws, c.w. nuts & washers.

2 off Forward mooring cleats (Y.S. No.7106 - 9 3/4" size)

8 off 1/4" UNC x 1 1/2" c/sk screws, c.w. nuts & washers.

2 off Mast step turning spool assemblies.

2 off 5/16" UNC x 2 1/2" screws, tapped in.

2 off Cheek blocks (Main Marine NCD-3).

4 off 5mm x 1 1/4" screws, c.w. nuts & washers.

2 off 5mm x 1 1/2" screws, c.w. nuts & washers.

5 off Bullseye fairleads (HA.152)

10 off No.10 x 1 1/4" red. c/sk s/t screws.

2 off cleats (Camcleats No. 201).

4 off 1/4" UNC x 1" c/sk screws, c.w. nuts & washers.

3 off UB.3 "U" bolts and 3 off 4-SK blocks (Main Marine).

1 off uphaul cleat (Camcleat No. 209).

2 off 5mm x 1" screws, c.w. nuts & washers.

1 off Mast step (Proctor 13A.103) c.w.

1 off Mast step pivot bolt (Proctor 202P97 and nut 3345)

4 off 1/4" UNC x 2" c/sk screws, c.w. nuts & washers.

6 off UB.9 "U" bolts for shroud plates (Main Marine).

4 off cheek blocks (Main Marine NCB-3).

8 off 5mm x 1 1/4" c/sk crews, c.w. nuts & washers.

4 off 5mm x 1 1/2" c/sk crews, c.w. nuts & washers.

1 off S/S Ventilite (Simpson Lawrence 1115-3) c.w. screws.

4 off No.6 x 3/4" p/h screws.

3 off No.6 x 3/4" c/sk rsd s/t screws.

4 off No.10 x 1 1/4" screws, c.w. nuts & washers.

1 off GRP moulding with sealant, as below.

2 off Foresheet tracks (BML-FT-40).

20 off 6mm x 1 1/4" c/sk crews, c.w. nuts & washers.

4 off 1/4" UNC x 1 1/4" panhead screws, c.w. nuts & washers.

2 off Bullseye fairleads for halyard (Holt Allen 152).

4 off No.10 x 1" raised c/sk self-tapping screws.

2 off Halyard winches (Barlow No.15 stubby).

8 off 1/4" UNC x 1" c/sk screws, c.w. nuts & washers.

2 off Foresheet sliding blocks (RWO No.266).

2 off Foresheet winches (Barlow No.16).

1 off Winch Handle (Barlow 10" Chrome).

1 off Winch Handle pocket (Plastimo 44.01.30.5).

4 off self-tapping No.6 panhead screws.

4 off Halyard and foresheet cleats (Camcleats No.201).

8 off 1/4" UNC x 1" c/sk screws, c.w. nuts & washers.

1 pair brackets (Saunders), 1 Mainsheet track (BML),

1 Mainsheet traveller & 1 pair adjustable end stops (IYE),

2 off 5/16" UNC x 2 1/4" hex. bolts c.w. nuts & washers.

1 off Tiller head fitting (Yacht Services 7152L).

1 off Backstay anchorage UB3 "U" bolt (Main Marine).

2 off Aft mooring cleats (Y.S. No.7110 - 6 3/4" size).

8 off 5mm x 1" c/sk screws, c.w. nuts & washers.

2 off UB.7 "U" bolts for backstay (Main Marine).

2 off Teak handrails (BML).

12 off No.10 x 1 1/4" c/sk screws and teak plugs

John, A24 list update : 395 Socrates : Now owned by Steve Carson. Falmouth.

ReplyDeleteHello, I just bought an Achille 24. I would like to speak about tips to make it better. I'm located in France in Aix les Bains.

ReplyDeleteHi, The best archive of information is on the old Flikr Site which has a search function for pictures which also have comments against them and for discussions. https://www.flickr.com/groups/achilles24/

DeleteFor current chat, questions etc then there is a Facebook group https://www.facebook.com/groups/828953110518954